1967 ›

Beginnings

First incorporated in New Hampshire, our company started by raising cattle and hogs for selling farm meat in 1967.

Maple syrup, produced on our own land, became a focal point for visitors, as well as honey from our own hives. In addition, Jolly Farmer products soon included freshly-pressed apple cider and home-made granola.

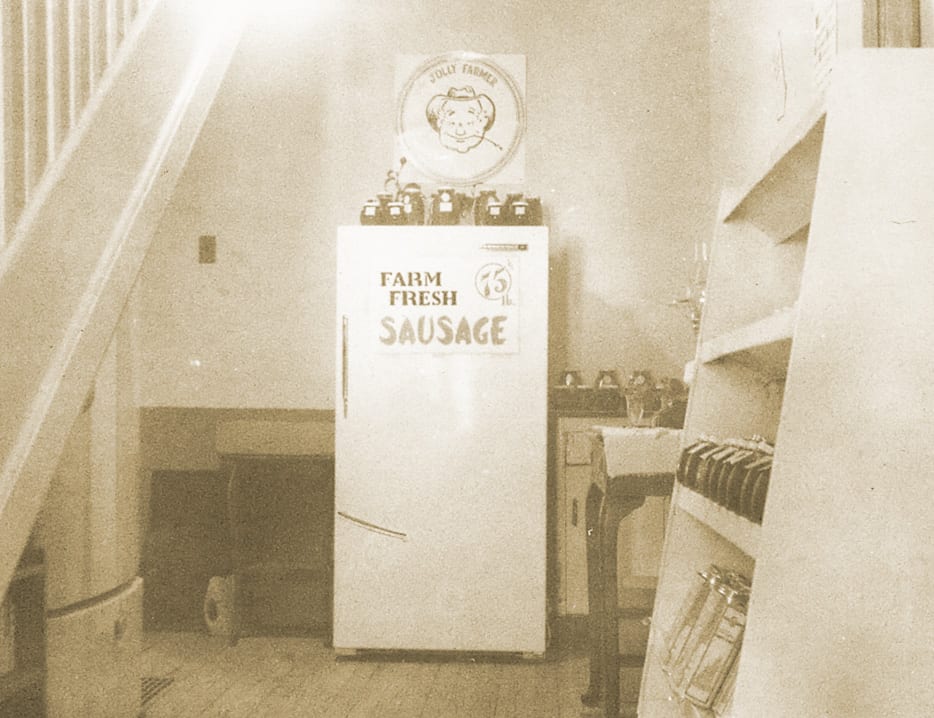

Jolly Farmer Sausage

The hallway where Jolly Farmer started selling its farm-raised pork. In the article pictured to the right, it was described: “People used to step inside the front door and ask where the store was… We had one refrigerator and one freezer.”

1979 ›

The Old Restaurant & Farm Store

The “Friendly Roost” operated out of this building during Jolly Farmer’s earliest years.

These delicious products inspired an expansion to a larger country store and restaurant using our own recipes and high quality farm foods. After adding a petting zoo, ice cream bar, and water fountain, the restaurant became the “Jolly Farmer Village” and was always landscaped using hundreds of flowers, grown on site and tended with care. With the fuel crisis in the late 1970’s, it became impossible to attract enough travelers to our location, and we transferred into a wholesale company selling our famous pies.

1982 ›

The First Greenhouse

Where It All Started

Jolly Farmer’s first greenhouse. The boy in the picture now works at Jolly Farmer as a grower.

Our love of growing things was the easy segue into the greenhouse industry. Started in 1982, our wholesale nursery offered flowering plants to garden centers in New England. Over the next few years, our one greenhouse quickly became 3, then 6, then 18, then finally 40. With the invention of the plug tray, we began offering seedlings, shipping our trays further and further afield until our market included all states of the continental US and even Alaska.

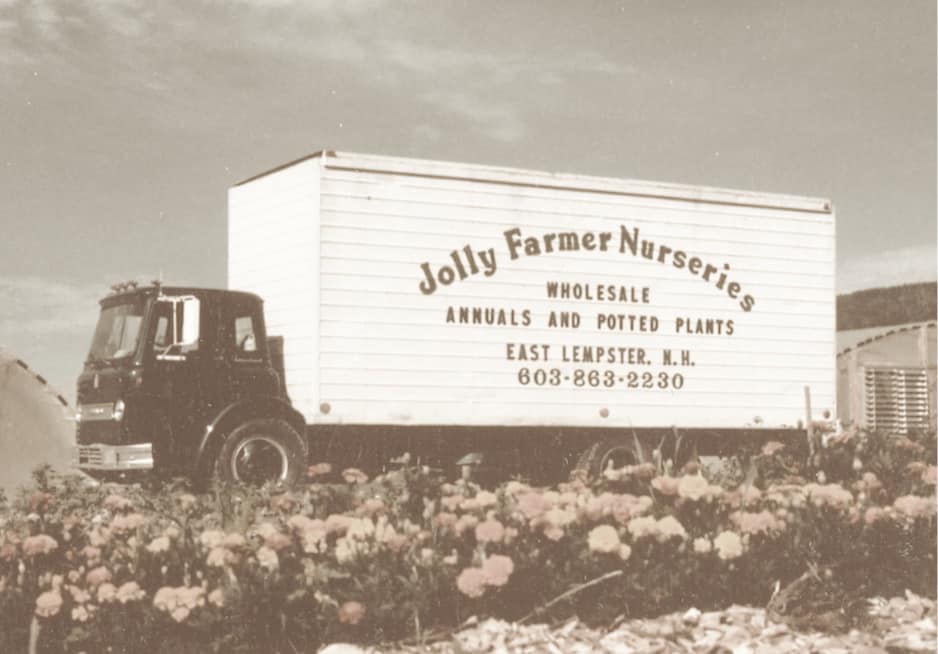

Jolly Farmer Transport

Back in earliest days, this small straight truck was the entirety of Jolly Farmer’s transport fleet.

1984-89 ›

New Hampshire Expansion – 1984

As we ventured into the newly developed plug market, we needed more space.

New Hampshire Aerial View

Even at full capacity in this facility, our orders exceeded the space allowed.

1996 ›

Move to Canada

Cut & Fill

Construction begins at the new greenhouse facility in New Brunswick, Canada.

Finding ourselves constricted for greenhouse space and available labor, we opened a second location in New Brunswick Canada in 1996. Constructed on a sloping piece of land purchased from H.J. Crabbe & Sons, Ltd, the greenhouse facility required a large cut-and-fill project to provide a level surface.

On 14 November, a fire started near the boiler room. It tore through the warehouse, destroying the heating system, and causing massive damage.

Back In Business

Only two months after the devastating fire, the new complex was operating again.

2005 ›

Expansion

Expansion

One year after moving to Canada, Jolly Farmer was building again, adding another 22 greenhouses. Greenhouse Canada’s May 1999 cover featured a photo of our greenhouse complex, with both phases completed, the same year we closed the New Hampshire facility.

Since 1996, we have expanded twice, bringing our total area under cover to approximately 10 acres. We’re pleased to say that we need to expand again! As we perfect our methods, our niche market of small to mid-size growers continues to increase. Our attempt to be a “one-stop shop” for them has really paid off, as well as our production teams’ efforts to minimize waste.

2008-17 ›

Innovation

2008 TTA Automated Patching

Mechanization not only helps with labor cost, but can also improve plant quality. When we introduced automatic patching – a process that removes empty cells and replaces them with viable plugs – we were able to reduce the number of seeds per cell. This in turn produces a more uniform and healthy plant, not competing for fertilizer, water, space, and light.

2014 New Benching

We upgraded both the benching and flooring throughout the first 36 greenhouses. The switch from asphalt floors to concrete will make it much easier to clean the floors, as will the benching which moves – with the push of a button – entirely to one side of the house. Aluminum will also prevent rust issues on the benching.

Some of the ways we’re honing our skills include both efficiency and mechanization. For example, we contracted with Flow Vision to help us reduce unnecessary costs. They trained us in new ways of thinking such as, “Every touch should add value”. If we are handling and re-handling and it does not in some way improve quality or service, we’re wasting our time. So we’re learning to work smarter, not harder. Their help in reorganizing our shipping system has increased our efficiency over 40%.

2010 MTZ Hanger Line

Previously, the thousands of baskets we grew every year hung in the structure above the benches, which made accessing them difficult and unsafe. Eventually we were able to switch them out for MTZ lines, which move the hangers around on a pulley system, allowing them to be watered by weight, and lowered down for shipping.

2017 Irrigation

Mus enimagn iscidunt harum il ipsa et lia vendi officid igenitiust, nonsendio. Otatium aut quistrum etur modia consed estrumenimus exerum rem quae Mus enimagn iscidunt harum il ipsa et lia vendi officid igenitiust, nonsendio. Otatium aut quistrum etur modia consed estrumenimus exerum rem quae

2018 ›

Phase 4

Phase 4

Mus enimagn iscidunt harum il ipsa et lia vendi officid igenitiust, nonsendio. Otatium aut quistrum etur modia consed estrumenimus exerum rem quae Mus enimagn iscidunt harum il ipsa et lia vendi officid igenitiust, nonsendio. Otatium aut quistrum etur modia consed estrumenimus exerum rem quae

Il enim esto totates aut lam, cusdae digendunt eossint orionet quaerestion ea deribusant eius, cor a dolut quam sit abo. Nequis ea que eius. Et ommolup tatestinctet pedi optaecae volorrum volestia vitempe rferias in rem qui sime con pel experia ntiaspeditio qui ut ducia poraepera sequo imilluptat in reptas exero conseque suntiosto omnia iusam rem ipsanis quid quae

2020 ›

New Office Building

Office Building

Mus enimagn iscidunt harum il ipsa et lia vendi officid igenitiust, nonsendio. Otatium aut quistrum etur modia consed estrumenimus exerum rem quae Mus enimagn iscidunt harum il ipsa et lia vendi officid igenitiust, nonsendio. Otatium aut quistrum etur modia consed estrumenimus exerum rem quae

Il enim esto totates aut lam, cusdae digendunt eossint orionet quaerestion ea deribusant eius, cor a dolut quam sit abo. Nequis ea que eius. Et ommolup tatestinctet pedi optaecae volorrum volestia vitempe rferias in rem qui sime con pel experia ntiaspeditio qui ut ducia poraepera sequo imilluptat in reptas exero conseque suntiosto omnia iusam rem ipsanis quid quae

2021 ›

Office Building

Complete